WELCOME TO GUITAR STRING MANUFACTURING

USA MADE PREMIUM WIRE

Electric Guitar - Acoustic Guitar - Bass Guitar - Banjo - Bajo Sexto Quinto - Mandolin

Resonator - Ukulele - Classical Guitar - Pedal Steel - Fiddle and more.

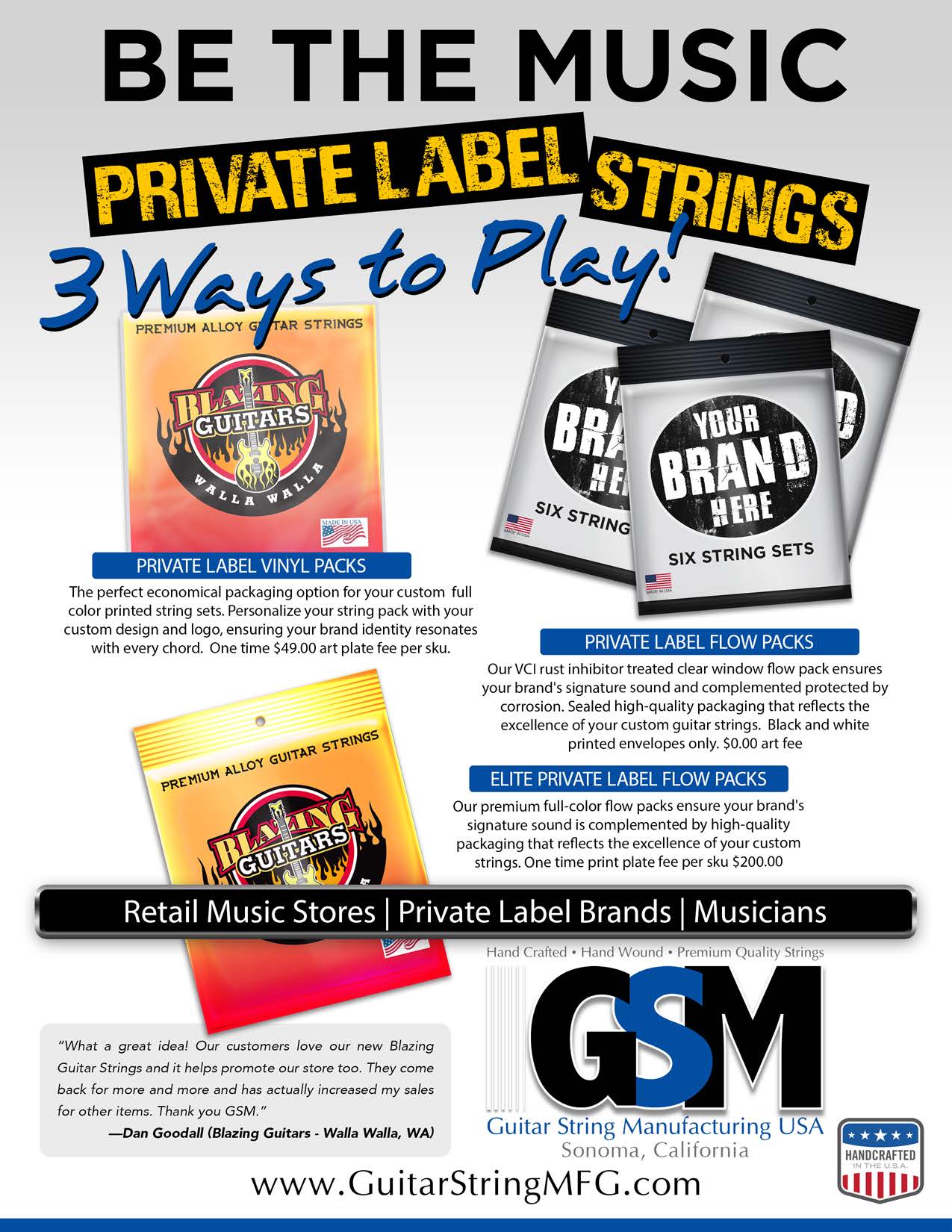

Launch Your Brand Without Breaking the Bank

Most string manufacturers require massive order quantities, locking you into big upfront costs before you even know if your product will sell. At GSM, we help you start smart. With low minimums and fast turnaround times, you can test the market, build your brand, and grow at your own pace—without sinking tens of thousands into inventory. Start lean. Scale fast. Grow with GSM.

More Than Materials — It’s About Mastery

What sets one string manufacturer apart from another isn’t just the materials — it’s the craftsmanship behind every inch of wire. At GSM, we obsess over the details that impact tone, sustain, and projection: Core-to-Wrap Coupling, Precision Pitch Angle, Wrap Speed & Core Tension.

Poorly wound strings might sound fine out of the box — but quickly degrade as weak coupling leads to tone loss. That’s why we ensure a precise bond between core and wrap for long-lasting clarity.

Our custom ball-end machines apply a perfect Twist-Loc™ to prevent slippage and breakage, eliminating tuning instability. Every string is triple-inspected, then hand-coiled and packaged to preserve quality from our shop to your instrument.

With 40+ years of supplier relationships, we source only premium, USA-made alloys — known for strength, consistency, and superior performance.

And unlike mass-production brands, every GSM string is handcrafted one at a time by skilled machinists who care about every note you play.

Need custom strings for your applications ?

GSM can do this for you!

Material Options

Nickel8 - High-output nickel/iron blend. Long sustain and powerful tone—perfect for players who want to cut through the mix.

Brass Masters - 80/20 brass formula. Balanced tone that lands between warm bronze and bright phosphor bronze.

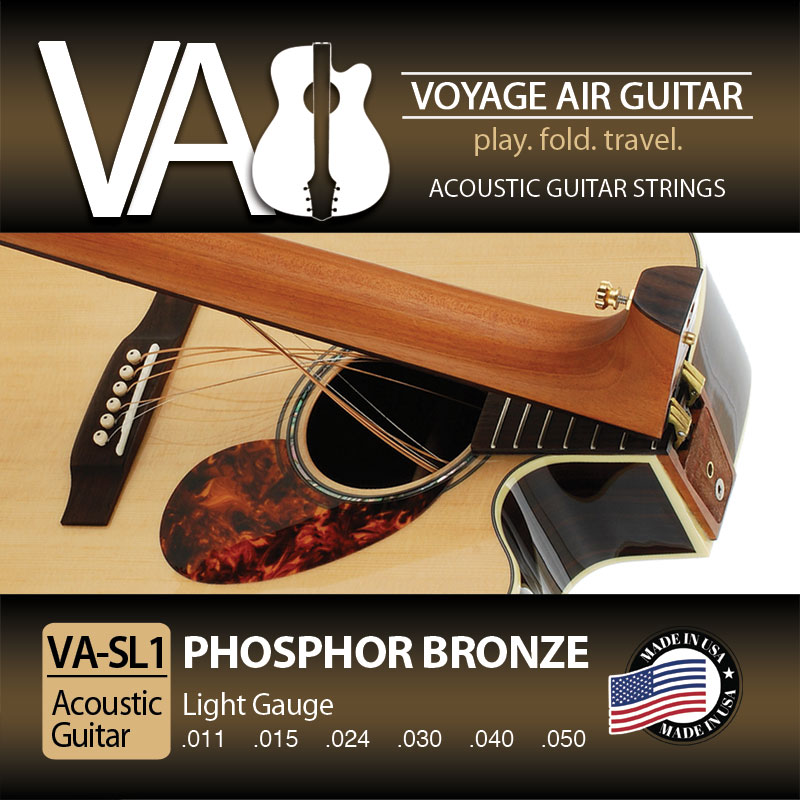

Bronze Masters - 92/8 phosphor bronze. The #1 choice of professionals for rich, all-around tone.

Stainless Steel - Built for resilience and durability. Delivers a bright, cutting sound with long-lasting performance.

Silverline Classic - Nylon rope, silk core wrapped with silver wire. Exceptional projection and brilliant classical guitar tone.

VCI Application Coating - Invisible protective layer. Shields against moisture and corrosion—without changing your tone.

GSM has had long-term relationships with raw materials suppliers that span over 40 years.

Although technology has evolved, USA materials have become more reliable and improved.

CUSTOMIZATION AND PACKAGING OPTIONS TO FIT YOUR NEEDS