Premium Crafted Musical Strings

GSM specializes in OEM and private label musical strings. Our company manufactures the finest fretted instrument strings available in the U.S.A. Collectively, our staff has 35 years of string making experience. We are one of the largest musical string manufacturers in the United States providing an exceptional quality USA made product that is shipped daily all over the globe.

Only the best USA Metal Alloy

GSM uses only the best USA made raw materials available. Our machines have been in operation for over 35 years producing musical strings for hundreds of custom brands. There is only a hand full of string manufacturers in the United States, and over the years we have made for over 200 brands worldwide, so we know what we are doing.

WELCOME TO GUITAR STRING MANUFACTURING

Electric Guitar - Acoustic Guitar - Bass Guitar - Banjo - Bajo Sexto Quinto - Mandolin

Resonator - Ukulele - Classical Guitar - Pedal Steel - Fiddle

Need custom strings for your applications ?

GSM can do this for you!

MATERIAL OPTIONS

Nickel8

Nickel8 is a unique blend of nickel/iron gives these strings high output with a long sustaining tone.

Brass Masters

Brass Masters 80/20 formula strings offer a "middle ground" of tone, falling between the warm bronze and bright phosphor bronze tones.

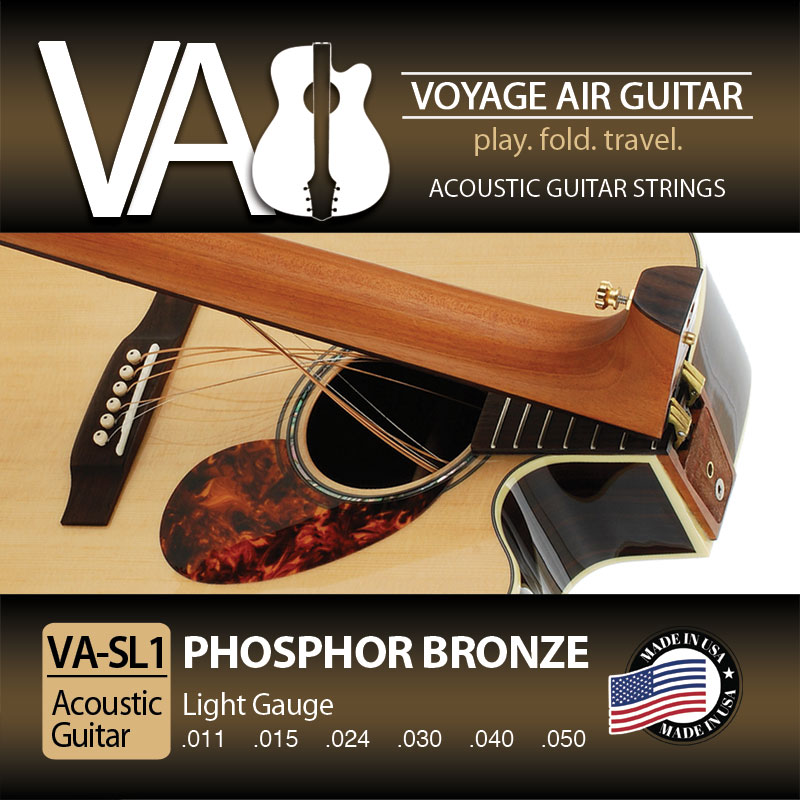

Bronze Masters

An excellent all-around phosphor bronze alloy 92/8 formula. The most popular choice of professionals.

Stainless Steel

This process creates a string that is more resilient than ever before – providing an optimized sound experience for any musician.

Silverline Classic

Silverline Classical is assembled using a nylon rope silk core wrapped with silver wire. Ensures the best overall projection and brilliant tone for classical guitars.

VCI Application Coating

This invisible layer prevents moisture and environmental elements from reacting with the metal surface and causing corrosion.

No job is too small or too big for Guitar String Manufacturing (GSM). Generally, other string companies' private label quantity requirements are

large requiring you to invest a ton of money into product and packaging. This can use up a lot of your capital just to get your company off the ground.

Our low minimum order quantity limits, along with quick turnaround, enable you to operate with low inventory, complete your initial test market and minimize your financial investment.

Once your brand starts to take off, we will grow with you! There is no need to throw tens of thousands of dollars into your new string business.

Start comfortably, and we will grow together.

More importantly is our quality. U.S.A made premium wire is the only wire we use

.

The differentiator between string companies is the type of material they use, the way the strings are constructed, and the

machines used to produce a final product. Not all strings are the same for this reason. Each manufacturer has its recipe when manufacturing a string.

There is the core-to-wrap configuration, a maintained pitch angle in which the wrap is applied, the speed at which the wrap spins, the tension at which the core wire is pulled and the machinists' long-term expertise in manufacturing musical strings.

Core-to-wrap coupling (the way the wrap is applied to the core ) is a huge factor. You cannot just spin wrap wire on a core and hope it sounds good. If the string isnt wound right, they may sound good for hours or days, however evetually loose its tone due to core to wrap coupling failure. The way the wrap is applied to the core is critical to the strings sustain, projection, and tone longevity.

Our one-off custom ball end machines ensure the right twist-loc around the ball is applied.

Without this, a string can either come off at the ball or slip which causes tuning problems. Each string is inspected three times, then hand coiled and placed into its envelope.

GSM has had long-term relationships with raw materials suppliers that span over 40 years. Although technology has changed, USA alloy materials have become better and more reliable.

Every string that comes off the production line is made by a machinist one by one. That machinist controls and maintains the consistency from string to string.

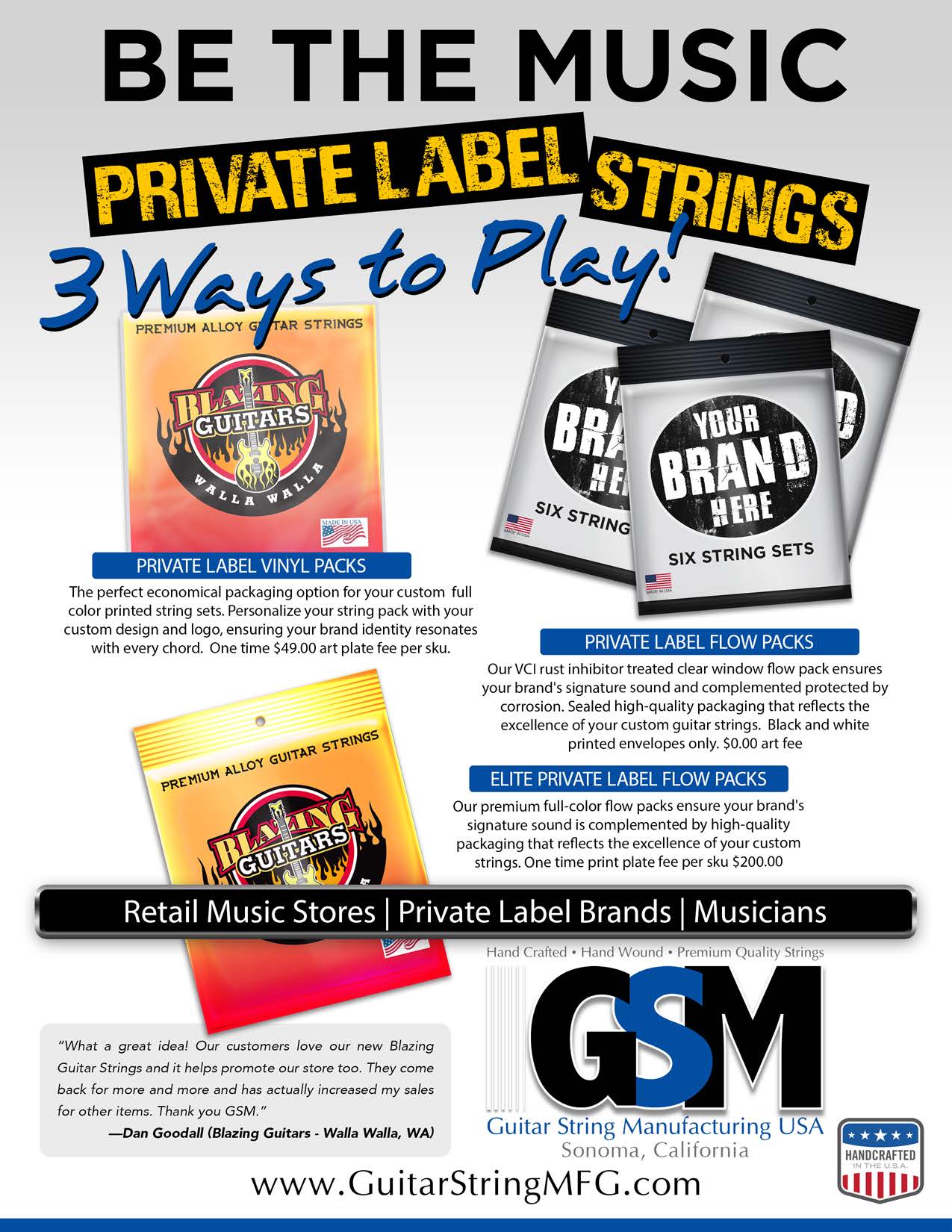

CUSTOMIZATION AND PACKAGING OPTIONS TO FIT YOUR NEEDS

Full color labels in a clear vinyl pouch - Full color sealed flow packaging - Bulk strings for your instruments or your touring needs

"I received the strings today. Put some 11s on; the artwork - perfect. Stringing them on and setting up, they felt incredible. Turned on the amp - they sounded even better than I expected them to be. Thank you so much. These things are BOLD! I love them, they feel and sound great" - NDA Customer